CNC milling machines are a manufacturing powerhouse that provides a high degree of scalability. However, the upfront cost of purchasing them and the recurring maintenance cost can prove to be a deterrent from owning such equipment.

In this regard, sourcing a CNC manufacturer for your project can be a highly effective trade-off that can achieve a similar effect without the associated headaches. Additionally, outsourcing this task means that you can enjoy pre-vetted work, higher profits, and protection from uncertainty.

But before you award the contract to the first manufacturer that you come across, here are eleven things you need to bear in mind while sourcing a CNC manufacturer for your project:

How Can You Set the Right Expectations?

Even though you may be sourcing the manufacturing job, it will require some amount of involvement at your end. This degree of involvement intensifies if you are looking for custom manufactured parts.

Unfortunately, most clients consider sharing the technical requirements as the end-all, be-all participation required at their end. Without getting into the capabilities and competencies of the CNC manufacturer, the first line of action would be to clearly enlist your expectations even before you start sifting through the prospects.

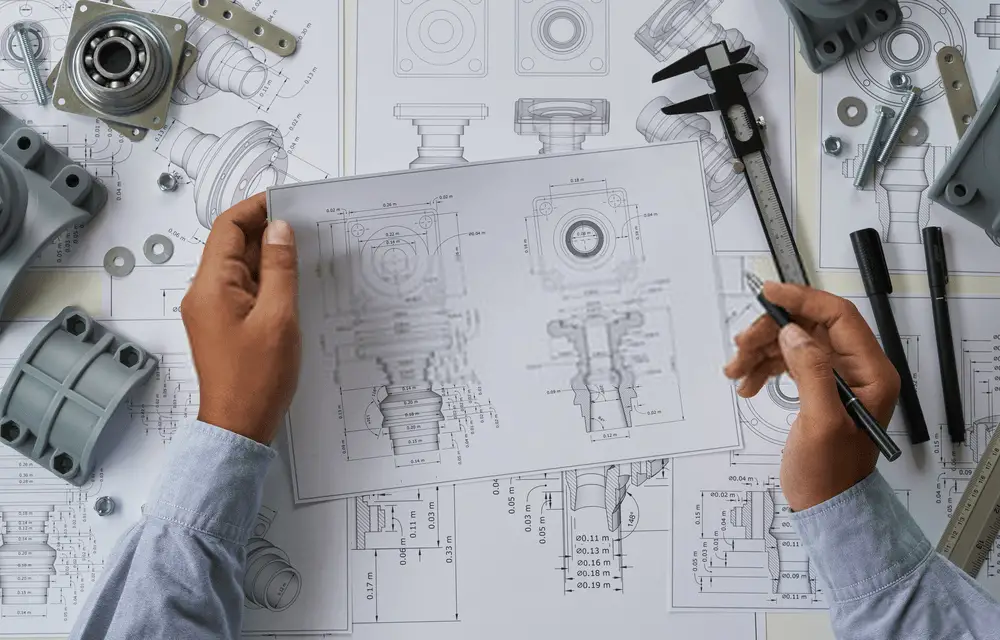

Hence, in addition to sharing the drawings, you will also have to explain the minimum passing requirements, material, tolerances, quality criteria, and schedule. Additionally, you may have to follow up with them to check on the progress or make corrections for errors.

Setting these expectations right at the beginning of the association will streamline the process.

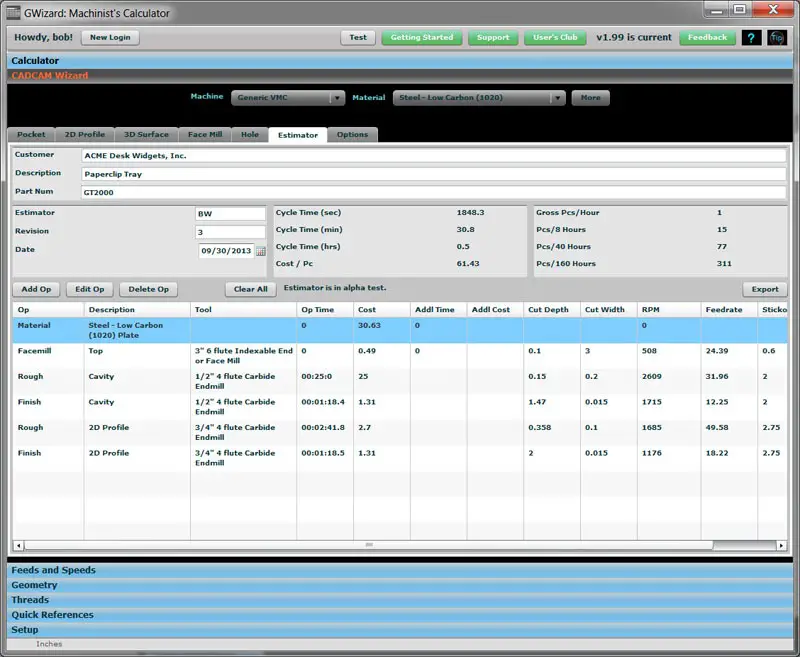

Can You Obtain Instant Quotes?

The back and forth communications for obtaining a quote can be the most frustrating and time-consuming part of sourcing parts from the CNC manufacturer. Traditionally, you will have to first raise the RFQ (request for quote) request and wait for the manufacturer to get back to you. In some conditions, you may even have to follow up and pursue the manufacturer to elicit a response. As a result, obtaining quotes can take anything from a few hours to a couple of days to weeks!

Fortunately, with the advent of technology, CNC manufacturers are offering actionable pricing almost instantly. Such systems require the client to upload the part drawing to analyze variables such as geometry, design complexity, features, finishing, etc., to generate an accurate quote for the custom component.

Does the Shop Offer Jobs in the Desired Materials?

Suppose you wish to place an order with a shop that has expertise in working with aluminum. However, would they still be your preferred manufacturer if the material were to change into something else, say titanium? The performance of the shop may vary in accordance with the changes of the alloy itself!

Ideally, you should hunt for a shop that has worked with a diverse set of materials. It is to their experience and expertise and indicates that they possess the requisite tools to carry out the job. Plus, it also ensures that you can still work with the manufacturer for your current as well as future requirements. This way, you can build long-term professional relationships.

Do They Have Good and Reliable Suppliers?

When choosing a CNC manufacturer, it’s necessary to check whether they have tools that are compatible with the desired material. But it is equally vital to consider their suppliers!

Unreliable suppliers could cause disruptions in the manufacturing process by shorting on raw material. They may even compromise the quality by delivering sub-standard material. For this reason, it’s recommended to seek details about their supplier and run a background check on their performance.

What Do the Company Profiles and Reviews Say?

Speaking of assessing performances and researching companies, it is also worth doing the same on the CNC manufacturers. Read up on the reviews of the past clients to know about the company’s work ethic and functioning.

Go through their profiles to evaluate their size, capabilities, annual output, and additional details on the facility. Most importantly, review their tools and equipment that go into the manufacturing process. The last thing you would want would be to award a contract to someone who does not possess a tabletop CNC mill when it is the key element to actualizing your design!

Can the Shop Build to Drawings While Factoring Tolerances?

Unfortunately, several shops run automated CNC mills with limitations while working on parts that go beyond the standard tolerances. In contrast, certain custom parts may require drawing interpretation. In this aspect, one needs to critically analyze the manufacturer’s designing capabilities while considering them for the task. Requesting for drawings after sharing the 3D file can be an excellent way to judge their competencies in the area.

If the design and tolerances are much more valuable than the time required to machine the part, it’s best to consider a shop that can scalably deliver spec manufacturing.

Do You Have to Commit to a Minimum Quantity?

Some machine jobs aim at low-volume, specialized production. In this case, they may have a comparable ratio of programmers or machine operators to the number of CNC milling machines. On the flip side, high-volume mass manufacturers could have a disproportionate number of machines when compared to the number of programmers.

While this ratio primarily determines the production capacity, it also has lingering effects on the cost component. And to make up for it, shops may impose a minimum quantity condition for accepting orders, which may prove to be an inconvenience and a hindrance from your original requirements.

Look for shops that can handle low-volume production without any minimum order quantity while balancing it with the scalability of their production capacity.

Does the Shop Perform Quality Assessment?

Having a dedicated quality control and assurance team is an indication that the shop takes its quality seriously. An internal quality assessment team can manage and validate operations by conducting routine in-process inspections (IPI) followed by a final review. Additionally, they can inspect tool conditions or calibrate the tools so that the CNC mills can offer optimum performance. Based on their findings that may be documented in a detailed report, the shop may approve or fail the part.

This consideration separates the fabricator from the inspector, which grants a subjective assessment of the part.

Can You Seek Assistance From an Expert?

Sharing files or designs and detailing the project requirements online are parts of a user-friendly experience. However, it robs clients of the consultative aspect that came into the picture while awarding contracts.

So what happens if you have a query or need advice while working on an absolutely new concept? You might wish to consult someone experienced in the field.

In such a scenario, live design-for-manufacturing customer support can come in handy. Expert manufacturing or design engineers can share guidance throughout the development process and also offer reasonable quotes based on the design and features. Any workshop that delivers customer assistance through phone, email, or chat would be well worth the investment.

Will the Shop Perform Secondary Operations?

Once the manufacturing is complete, the final product may require secondary processes, such as chemical coating, waterproofing, anodizing, nickel plating, powder coating, electropolishing, etc. Additionally, they may also require post-finishing touches in the form of silkscreens, laser marking, or insert installations that would be necessary before shipping the final product.

If you seek turnkey solutions where you can unpack the part and put it directly to use, then speak to the manufacturer to know if they offer such services.

Can You Place Sample Trial Orders?

Once you have shortlisted a few manufacturers who can produce the desired products, feel free to request samples to adjudge their capabilities. It will serve as a snapshot of the kind of service and product that you can expect from the manufacturer. Even if you proceed with another manufacturer, pay a reasonable amount for the samples, especially when they meet your expectations.

Of course, you will have to impress upon the manufacturers that their performance and delivery at this stage will act as a benchmark for your future association. As such, the bulk products should remain as good as the samples and vice versa.

Are You Ready to Source Your CNC Manufacturer?

To reiterate, sourcing a CNC manufacturer can be highly cost-effective and beneficial for your business. The only challenge is to find a reliable manufacturer who can fulfill your requirements. Fortunately, the guide shared above can lend you direction and help you narrow down your options until you find what you seek.

About the Author:

Peter Jacobs is the Senior Director of Marketing at CNC Masters. He is actively involved in manufacturing processes and regularly contributes his insights for various blogs in CNC machining, 3D printing, rapid tooling, injection molding, metal casting, and manufacturing in general.

![Types of Engineers and What they Do [Explained]](https://www.engineeringpassion.com/wp-content/uploads/2022/04/types-of-engineers-and-what-they-do-280x210.jpg)

Leave a Reply