Shipping container architecture is a fast growing method of architecture using steel intermodal shipping containers as the main structural element of the intended design. Nearly, all shipping or cargo containers are made of high quality steel and have closed-top with hinged doors. They have corrugated surrounding walls on the top and bottom sides and are welded to the rails and end frames.

The steel used in the construction of containers is not only strong, but meant to withstand heavy loads and tough weather conditions. Currently, the world has over 60 million shipping containers in use, making them widely accessible for alternative uses and a reasonably cheap and sustainable building material.

Re-using any item or product decreases the potential negative impact on the environment and, so is a green choice. The 3 Rs of sustainability are Reuse, Reduce and, Recycle. Thus shipping containers made of steel or aluminum have been re-used in thousands of construction projects around the world as the building blocks for a wide variety of buildings which include but are not limited to:

- Houses

- Offices/On-site Offices

- Apartment Complexes

- Labs & Medical ICUs

- Small Schools

- Offshore Living

- Coffee Shops

- Retails

The more we use shipping containers for alternative purposes, such as house design, the more we will reduce the number of idle shipping containers and thus contribute to save the environment from pollution, and create an exceptionally designed project.

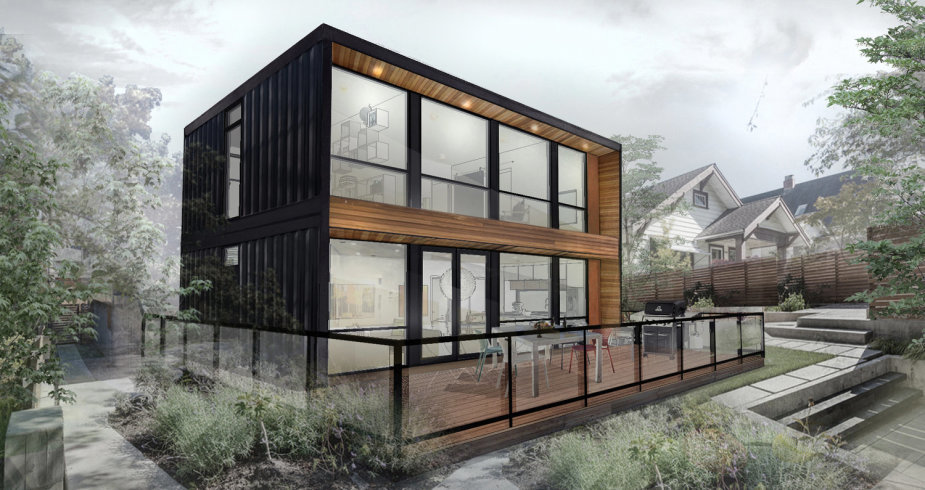

Shipping Containers House Design

Shipping container are used for different purposes, for instance, recently engineers converted shipping containers into mobile ICUs in Turin, Italy to combat COVID-19 pandemic. The trend of ‘shipping container architecture’ is on rise in the recent years. Houses of all shapes and sizes are made from the giant LEGO like blocks of shipping containers.

The smallest container makes a tiny box of a house at about 10 sq. meters of floor area. Eight larger containers arranged together can make a two-story house at about 130 sq. meters of area. Hundreds of container micro-apartments arranged together can make an enormous apartment building.

But you are probably thinking, why are shipping containers being used to make such houses, apartments, studios, cabins, and offices? Well, there are millions ‘out-of-service’ containers available in the world, and it would be fantastic to play with these giant blocks to make fantastic structures and not let them go unused!

Besides trendiness, interest in container house design is also portion of a wider interest in saving money with pre-fabricated and modular homes. Many homeowners prefer to save money on both construction and maintenance of new house design. Could a container home be a good and worthy choice for you? Let’s check the pros and cons of container homes!

Pros of Shipping Container Houses

Construction Cost: An abundant amount of used containers are available at a price that is low compared to a house built with expensive foundation and built entirely out of bricks and mortar. Construction of house using containers involves very little labor work and used containers require only minor modifications and can be purchased from major transport companies for as little as $1,200 USD each and less than $6,000 USD for a brand new one.

Strength and durability: Shipping containers are made of high quality steel and thus they are an ideal building structural material. They are designed to bear heavy loads and to be stacked in high columns. They are also designed to resist harsh weather conditions and environments, such as on ocean-going vessels or sprayed with road salt while transported on roads. Due to their high strength, containers are valuable for safe storage.

Pre-fabricated and Modular Units: All shipping containers are made with standards in mind, they come in standard dimensions and measurements and as such they provide modular elements that can be combined to make a larger structure. This simplifies the design, planning and transport processes. As they are already designed to interlink for ease of mobility during transportation, structural construction is completed by simply installing them. Due to the containers’ modular design, additional construction is as easy as stacking more containers.

Labor Work: The welding and cutting of steel is considered to be specialized labor and can increase construction costs, yet overall it is still lower than conventional (brick and mortar) construction. Unlike wood frame construction, attachments must be welded or drilled to the outer skin, which is more time consuming and needs different job site equipment.

Transport: Pre-fabricated modules can also be simply transported by cargo ship, truck or rail, because they already conform to standard shipping sizes.

Availability: Plenty used containers are available around the world.

Cons of Shipping Container Houses

Temperature: Steel is a good conductor of heat; containers used for human occupancy in an environment with extreme temperature variations will normally have to be well insulated than most traditional brick, block or wood structures. If container facilities are not well insulated they will be very warm in summer and too cold in winter.

Humidity: As mentioned above, the forming material of a container (steel) is a good heat conductor. In temperate climates, moist interior air condenses against the steel, becoming clammy and unpleasant. Rust will form unless the steel is well sealed and insulated.

Construction Site: The size and weight of the containers will, in most cases, require them to be placed by a crane or forklift as compared to traditional brick, block and lumber construction materials which can often be moved by hand or hand trucks, even to upper stories.

Building Permits: The use of steel for construction, while widespread in industrial construction, is not widely used for residential structures. Obtaining building permits may be troublesome in some regions due to municipalities not having seen this application before or local laws and regulations.

Cargo Spillages: A container can carry a wide variety of cargo during its usage period. Spillages or chemical contamination may have occurred on the inside surfaces and will have to be cleaned for human habitation. Ideally all internal surfaces should be abrasive blasted to bare metal, and re-painted with a nontoxic paint system.

Damage: While in service, containers are damaged by friction, handling collisions, and force of heavy loads overhead during ship transits. The companies will inspect containers and condemn them if cracked welds, twisted frames or pin holes are found, among other faults.

Solvents: Solvents released from paint and sealants used in manufacture might be harmful.

Container House Design Costs and Expenses

Smaller, more basic container houses cost can range between $10,000 USD to $35,000 USD. Large homes built with multiple shipping containers stacked together and facilities can range in price from $100,000 USD to $175,000 USD. Shipping container homes, in some cases, can even cost half as much per sq. meter than traditional building. However, it’s not easy to compare the prices, as there are many factors in addition to the land costs and proper climate requirements, that should be taken into consideration:

- Size, Layout Plan, Design, and the Number of Shipping Containers

- Welding and Fabrication Requirements

- Plumbing and Electrical Installation

- Cleaning cost (used containers)

- Kitchen and Bathroom Finishes

- Structural Reinforcement

- Insulation

- Windows

- Flooring

- Doors

- Siding

- Lofts….

So whether you’re an individual looking for a creative new project, a business owner in need of supplementary storage, or an engineer searching for new structures that can be converted into homes for people, shipping containers might be exactly what you’re looking for. If you’ve already built a container house or facility, feel free to share your work with us.

![Types of Engineers and What they Do [Explained]](https://www.engineeringpassion.com/wp-content/uploads/2022/04/types-of-engineers-and-what-they-do-280x210.jpg)

This is some really good information about shipping container houses. I never thought about buying a shipping container for that. It is good to know that you will want to consider how to go about insulating the container and adding windows.