The civil engineering and construction industry is an ever-evolving field, and the innovations that are happening in the industry are nothing short of amazing. As a result, civil engineers must continually adapt their methods and practices to stay ahead of the curve.

And while it’s not always glamorous work, it can be very rewarding to know you’re helping build something new for a community.

From skyscrapers & bridges to residential buildings & single-family houses, civil engineers are doing some amazing things with their knowledge of building materials and techniques.

In this article, Engineering Passion has put together a list of innovative technologies that could change how buildings and structures are built better, faster, and more efficiently in the future.

Table of Contents

1. 3D Concrete Printing

2. Smart Watches for Construction Workers

3. Building Inspection Robots

4. Kinetic Footfall

5. Bionic Exoskeletons

6. Self-healing Concrete

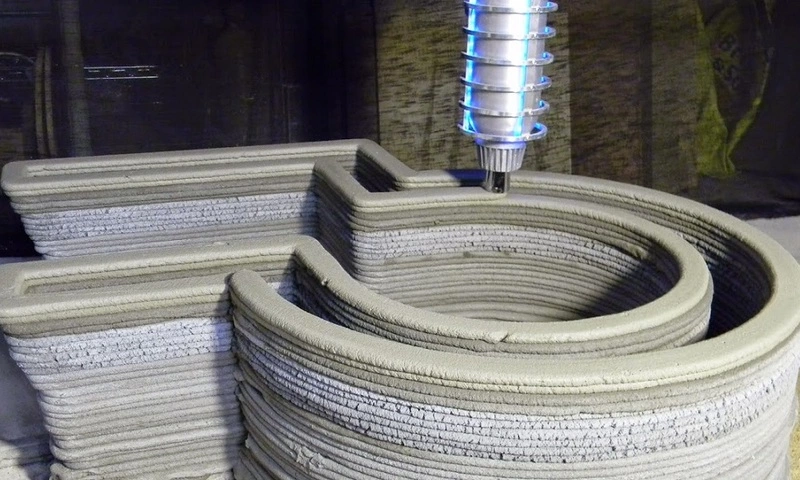

1. How is 3D Concrete Printing speeding up the building process

The use of 3D printers is becoming more and more common in a variety of industries, and the construction industry is no exception. In 2021, 3D printing comprised around 0.1% of the global manufacturing market. In 2019, the global 3D printing market was worth over $10 billion. [1]

Fun fact: Plastic is the most used material for 3D printing (82%).

3D concrete printing is a relatively new technology that is being used to create all sorts of different structures, from homes to office buildings. 3D Build Systems, an American company based in Florida, creates concrete printing robots that can create durable, scalable, and customizable structures using a mix of concrete.

The company’s robotic technology reduces construction time by printing walls in 12-24 hours. Not only that, the robots can work with most 3D modeling applications and print walls up to 7 meters in height.

The company provides economical and well-constructed housing using robotics and 3D printing technology and its mission is to design, build and deploy a Robot that could 3D Print a home using cement or other approved building materials in 24-36 hours and meet all building codes for that specific region.

2. Smart Watches for Construction Workers

Most people are familiar with smartwatches, but did you know that there are now smartwatches specifically designed for construction workers? These watches are equipped with a variety of features that can help boost productivity while making construction worksites more connected and safe.

IoSite is a startup based in the United States that produces IoT-powered smartwatches for construction industry workers. The main goal of these smartwatches is to monitor the health conditions of remote on-site workers.

Smartwatches help managers keep track of employee well-being by monitoring worker conditions and sending real-time updates, job progress, and periodic health reports during check-in and check-out. It also sends emergency notifications to ensure worker safety in remote locations.

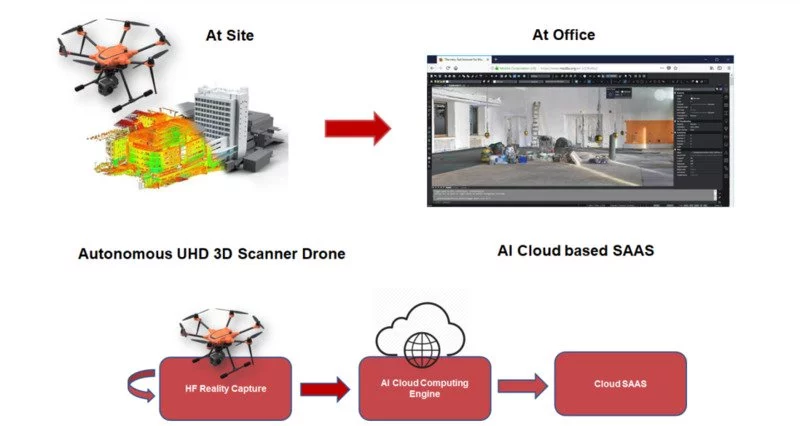

3. Building Inspection Robots are helping to save time and money.

Another innovation that is changing the construction industry is the use of robots for building inspections. Building inspectors traditionally have to go into dangerous and difficult-to-reach places to assess the condition of a structure.

Now, there are robots that can do this job for them.

Holoarch, a Tel Aviv-based firm, uses cloud-based and hardware technologies to help engineers inspect buildings on site. In fact, their solution is a mixture of a Drone, 3D Scanning Lidar, and Artificial Intelligence – all in one system!

The company’s robotic solution, Holobot, is an autonomous drone that inspects construction sites and reports faults to the authorities. It enables constructions companies and inspection professionals to reduce time & money, by making super fast & high-quality 3D digital twins using industrial-scale drones.

The global inspection robots market size was valued at $940.0 million in 2020 and is projected to reach $13,942.5 million by 2030, growing at a CAGR of 30.9% from 2021 to 2030. [2]

4. Kinetic Footfall can help to create sustainable energy.

The floors in our homes and offices are usually pretty sturdy, but what if they could actually generate energy? This is the idea behind kinetic footfall, a technology that converts the energy from human movement into electricity.

Pavegen is a UK-based company that produces floor tiles that harvest the energy created by footsteps and convert it into renewable electricity. The company’s patented technology has been installed in over 500 locations worldwide, including Heathrow Airport, Coca-Cola Arena, and West Ham United Football Club.

The kinetic energy generated with each step is absorbed and converted into other applications. Everything from dynamic LED displays to intelligent multimedia, gamification, green walls, and more are possible thanks to this technology.

The kinetic footfall is most beneficial for transporting hubs where a large number of people will pass over it. The company has been using this technology in transport hubs, retail, brand activation, and smart cities among other settings.

5. Bionic exoskeletons are being used to help construction workers.

Exoskeletons are devices that are worn by humans to enhance their physical strength and abilities. They are often used in industrial and construction settings to help workers lift heavy objects or perform tasks that require a lot of physical labor.

Bionic exoskeletons are a type of exoskeleton that uses robotic technologies to amplify the wearer’s strength. They are often used by people who have mobility impairments or those who need extra support to perform their jobs.

Ekso Bionics is one such US-based company that engineers industrial wearable bionic exoskeletons for various industries including the construction industry.

Workers in the construction business are frequently restricted by national laws that restrict them to a maximum weight of 25 kg. Bionic exoskeletons mean that the strength of these workers can be significantly enhanced, with little effort needed by the operator to handle this weight.

6. Self-healing Concrete is being developed to repair itself.

Concrete is one of the most widely used materials in construction. It is strong, durable, and affordable. However, it is also susceptible to cracking and other damage which is usually caused by exposure to water and chemicals. Self-healing of concrete is the process in which the material regenerates itself by repairing inner cracks.

A group from the Polytechnic University of Valencia (UPV) and the Politecnico di Milano created a new ultra-resistant and self-healing concrete material within ReSHEALience, a European initiative. It has 30% greater strength and durability to endure cracking when compared to high-performance concrete, according to the study.

Another advantage of these modern cementitious materials is their decreased maintenance requirements, which allow civil engineers to go beyond the current design’s standards (50 years). Thanks to the self-healing processes, it can automatically mend any cracks if they arise.

Bottom-line

By keeping up with the latest advances in technology, civil engineers can position themselves at the forefront of their field. As we move into the future, it is clear that innovation will continue to play a vital role in the civil engineering and construction business.

These six examples are just a few of the many that are helping to shape the future of the industry. With these advances, we can expect to see more efficient and sustainable buildings, longer-lasting infrastructure, and safer working conditions for those in the construction industry.

References:

[1] https://cybercrew.uk/blog/3d-printing-statistics/

[2] https://www.alliedmarketresearch.com/inspection-robots-market

![Types of Engineers and What they Do [Explained]](https://www.engineeringpassion.com/wp-content/uploads/2022/04/types-of-engineers-and-what-they-do-280x210.jpg)

Leave a Reply