Ultimately, every contractor usually aims to deliver their projects within the specified time frame and within the budget. One of the best ways to do this while making construction more cost-efficient is to always be prepared for anything.

Many companies receive requests to conduct underground utility surveys even before ground breaking has been done on a construction site. Though this is a great way to avoid labor strikes once the project commences, early surveys can also identify buried utilities which may need to be modified before construction starts.

Underground utility surveys using ground-penetrating radar can be compared to foresight. By carrying out surveys early, the construction plans by an architect can be modified and optimized to incorporate any design changes required because of utilities before any construction permission is sought.

Why Use GPR (Ground-penetrating Radar) Technology?

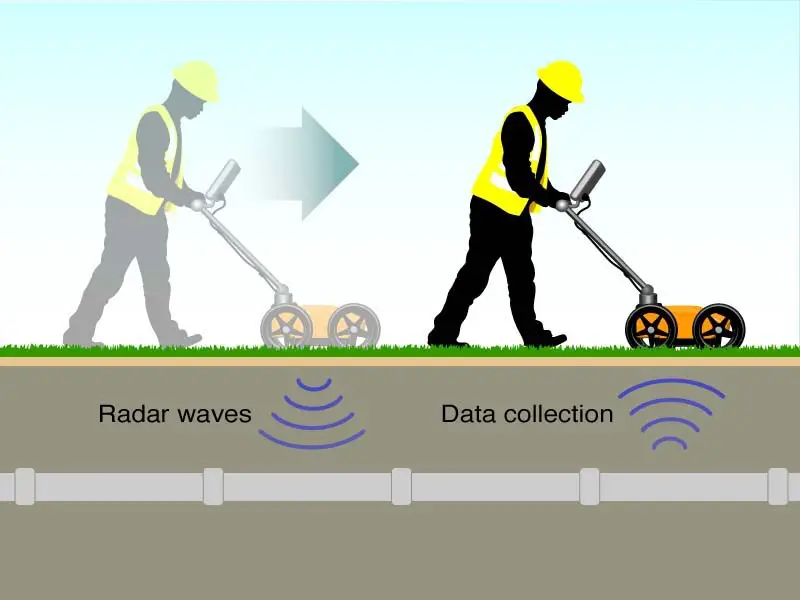

Conventional methods of electromagnetic tracing and location have limitations, since they need to induct a signal. These traditional methods aren’t able to identify all underground utilities anymore, given the widespread usage of fiber optic cables and polyethylene gas, among others. Alternatively, a ground-penetrating radar survey can detect subsurface pipes both metallic as well as non-metallic alike. This kind of survey method is neither intrusive or destructive, and it uses electromagnetic radar pulses in the radio spectrum in order to ascertain and record any structures that are beneath the ground.

This kind of method is quite reliable and among the safest methods for mapping out drainage, water pipes, fiber optics, and other underground utility infrastructure. GPR technology is able to generate underground maps that are translated into fully three-dimensional drawings and imagery by CAD specialists. Such drawings are useful in planning utility projects and figuring out where further underground services may or may not be placed.

Pros of Carrying Out Underground Utility Surveys:

#1 Design and Planning

Having a full understanding of all utilities in a work-site means that a construction project only has to be designed once.

Additionally, from the information gleaned during a survey, you can identify the best way for supplies to be delivered at your construction site based on the available utilities. Further, you also get to understand where you may have to divert utility lines.

By understanding the existing utilities, you also get to avoid potential design pitfalls. For example, in a recent survey done for an electrical connection project, we identified a gas line meaning that the contractor got to know the distance the power line had to maintain from the gas line. Another great thing about surveys is that they allow you to have a 3D view of the entire project meaning that you will be in a better position to choose the right contractor.

#2 Health and Safety

By understanding your work-site, you are able to minimize the risk of incidents, prevent accidents and also deter service strikes by workers. Undertaking underground utility surveys can help in making the construction site safer for workers and the general public.

#3 Cost-Efficiency and Timely Completion of Projects

Understanding what lies below a construction site means that you will be aware of potential obstructions which may have resulted in labor downtime as the project is ongoing if they were not identified earlier. By undertaking underground utility surveys, you can avoid the additional costs like screw piles, that come with a delayed project. Engineers should use time management tips to maximize productivity and for successful completion of their projects.

![Types of Engineers and What they Do [Explained]](https://www.engineeringpassion.com/wp-content/uploads/2022/04/types-of-engineers-and-what-they-do-280x210.jpg)

I like that you pointed out that doing this procedure will prevent you from having design pitfalls when you plan to have a structure constructed in a certain place. I will suggest to my sister to look for services like this before having her dream house constructed on the lot she bought. It’s just to make sure because the lot is really affordable which made me think that there must be something, but I hope not.